Custom Core Making

Never Miss a Beat with our Cores

Allocate your labor resources to more critical areas of your foundry

and let us make your cores. Let Kore Mart become an extension of your core room.

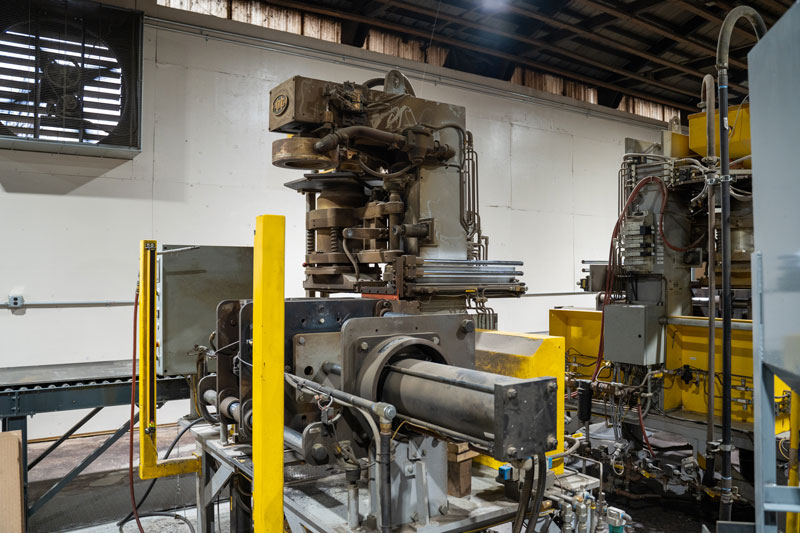

Equipped with high production shell and cold box machines. Whether it is staffing issues, tooling issues, or capacity issues, Kore Mart is ready to relieve your core making headaches.

Fast Lead Times

We shoot for 2 weeks maximum lead time. We understand that the foundry has many steps after pouring the casting, and we want you to get started right away.

Core Machine Capabilities

| Process | Number of Machines | Machine | Width (in) | Height (in) | Depth (in) | Invest (in) |

|---|---|---|---|---|---|---|

| Shell | 4 | Redford 22 RA | 22 | 24 | 16 | 22 |

| Shell | 2 | Redford 16 RA | 16 | 18 | 14 | 16 |

| Shell | 2 | Redford 22 SA | 22 | 24 | 16 | 22 |

| Shell | 2 | Shalco U180 | 29 | 20 | 16 | 15 |

| Coldbox | 1 | CB30 – Horizontal | ||||

| Coldbox | 2 | VSTB | 22 | 24 | 16 | 22 |

Tooling

We can assist with the creation of new tooling in conjunction with local patten makers to ensure the work gets done accurately and timely. In cases of existing tooling, at no charge, Kore Mart will equip your tooling with the proper mounting for our machines.

Raw Materials

For Shell, Kore Mart uses its own custom blended RCS that we make on site. We use the finest round and sub-angular sands on the continent. Mixed with state-of-the-art phenolic resin and proprietary release agents, we can make cores to suit any metal type, casting size, surface finish, or get around troublesome defects. For Cold Box, we primarily use 60 Round sand with anti-veining additive when needed. Upon request we can make cold box cores with sub-angular sand.

Careful Packaging

We take great care in packaging your cores to safeguard them during transit. Our team utilizes appropriate packaging materials and techniques to protect your cores from any potential damage. 95% of our cores ship out with one-way packaging, which means it is non-returnable. This inexpensive yet solid and convenient packaging option eliminates having to deal with dunnage and return credits.